Department of Mechanical Engineering

Challenges to Breakthrough of “Machines” to Support a Sustainable Society

Concept

Since the industrial revolution of the 18th century, “machines” have advanced greatly to become widespread across the globe. They have become the driving force of industrial development, supporting our societies across various areas.

Nowadays, the concept of “machine” is expanding further, together with technological advances such as information technology, and fusing with related fields such as electronics, bioengineering, and medicine. This includes intelligent machines and robots, information devices connected to networks, and machines functioning in extreme or micro environments that were previously unimaginable.

Mechanical engineering is a basic discipline that has supported this evolution of “machines”, and the various technologies related to “machines” and “manufacturing” are the culmination of the efforts devised by many engineers and researchers majoring in mechanical engineering. However, the development of industries through mass production and mass consumption has also caused global energy issues and environmental problems. Therefore, mechanical engineers now play a vital role in contributing towards the realization of a “sustainable society”, which is safe and secure and has less impact on the environment. They must also aim to solve these related issues from a global perspective, considering the social influence of science and technology.

The Department of Mechanical Engineering keeps challenge towards the breakthrough of “machines” that drive new technological innovations capable of supporting such a “sustainable society”. We continue to cultivate mechanical engineers and researchers who can respond to the demands of future society.

-

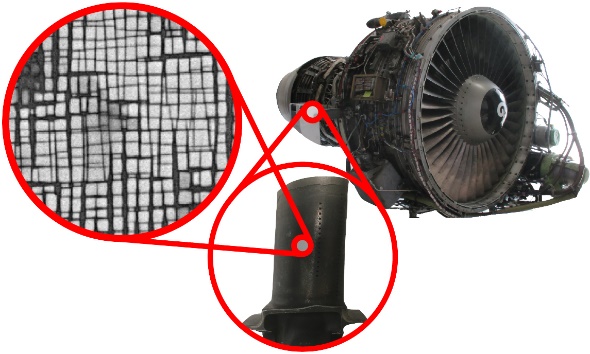

Energy equipment (gas turbine)

Courtesy of Kawasaki

Heavy Industries, LTD

-

Social infrastructure

(Great Seto Bridge)

-

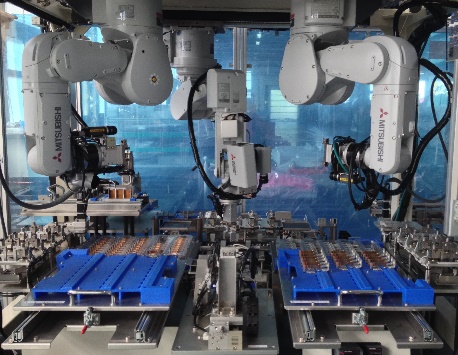

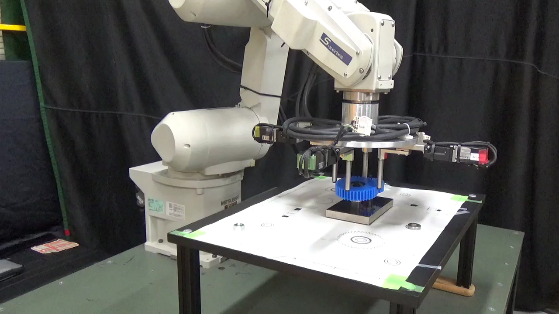

Next-generation production

system (robotic production cell)

Courtesy of Mitsubishi Electric Cooperation

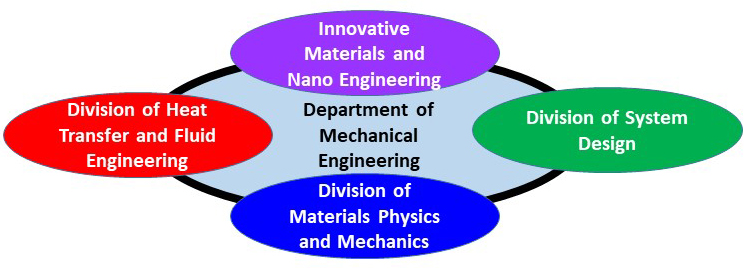

Structure and Divisions

The department of Mechanical Engineering was established in 1921, one of the oldest departments in the University. It produces many leading engineers in mechanical engineering. The department has four divisions: Heat Transfer and Fluid Engineering, Materials Physics and Mechanics, System Design, and Innovative Materials and Nano Engineering. Research programs are offered in 11 fields.

Division of Heat Transfer and Fluid Engineering

Towards realization of sustainable society, complex phenomena with heat and mass transfer in fluid systems in human body, energy systems including power and refrigerating systems, natural environment, and so on, are being investigated theoretically, experimentally, and numerically.

Division of Materials Physics and Mechanics

The mission of this division is to promote research and education of mechanical and physical properties of materials through analytical, numerical, and experimental evaluation of structures and machine components. Formation of advanced materials is also studied in this division.

Division of System Design

The mission of this division is to establish engineering solutions required for developing active but sustainable next generation social systems from the viewpoints of system design. Towards this goal, we conduct education and research on system analysis and design, intelligent robots, advanced devices, and next- generation manufacturing technologies that cover a wide range of phenomena at micro and macro levels.

Division of Innovative Materials and Nano Engineering

The mission of this division is to develop novel and advanced functional mechanical systems for a sustainable next generation society from a viewpoint of nano/micro to macro scale levels; for example, developments of body implantable mechanical systems, wearable sensors for health monitoring.

Laboratories and Faculties

Division of Heat Transfer and Fluid Engineering

Advanced Fluid Engineering[MH-1]

| Professor | Yohsuke IMAI |

| Associate Professor | Takeshi KATAOKA |

| Assistant Professor | Shunichi ISHIDA |

Keywords:

Computational biomechanics, Biofluid mechanics, Computational fluid dynamics, Digestive fluid mechanics, Capsules and cells, GPU computing, Nonlinear flow phenomena, Water wave, Internal gravity wave, Breaking wave, Acoustic wave, Stratified fluid

Multiphase Fluid Dynamics[MH-2]

| Professor | Akio TOMIYAMA |

| Associate Professor | Kosuke HAYASHI |

| Assistant Professor | Ryo KURIMOTO |

Keywords:

Bubble dynamics, Drop dynamics, Mass transfer, Computational multiphase flow dynamics, Nuclear thermalhydraulics, Gas-to-liquid, Multiphase flows in microchannels, Two-phase pipe flows

Energy Conversion Engineering[MH-3]

| Professor | Hitoshi ASANO |

| Associate Professor | Hideki MURAKAWA |

| Assistant Professor | Katsumi SUGIMOTO |

Keywords:

Boiling and condensation heat transfer, Heat exchanger, Thermal control devices, Ultrasonic measurement, Neutron radiography, Fuel cell, Refrigerating and heat pump system, Geothermal utilization

| Technical Staff | Naoyuki YOSHIDA |

Division of Materials Physics and Mechanics

Structural Safety Evaluation[MM-1]

| Professor | Takahide SAKAGAMI |

| Associate Professor | Daiki SHIOZAWA |

| Assistant Professor | Yuki OGAWA |

| Visiting Professor | Shiro KUBO |

Keywords:

Structural integrity evaluation, Inverse problem, Non-destructive evaluation, Maintenance engineering, Infrared measurement, Teraheltz electromagnetic waves measurement

Fracture Control Engineering[MM-2]

| Associate Professor | Masahito TAGAWA |

| Hiroshi TANAKA | |

| Research Associate | Kumiko YOKOTA |

Keywords:

Strength of engineering materials, Micromaterial, Metallic material, Composite material, Space materials, Space envirnmental effect, Electric propulsion, Beam-induced surface reaction

Structural and Functional Materials[MM-3]

| Professor | Katsushi TANAKA |

| Associate Professor | Yoshikazu FUJII |

| Tadashi HASEBE | |

| Assistant Professor | Takeshi TERAMOTO |

Keywords:

Heat resistance structural materials, Functional materials for energy harvesting devices, Multiscale simulations for analysis and predicting material performances

| Technical Staff | Yukio KOUDA |

Division of System Design

Function-Oriented Robotics[MA-1]

| Professor | Yasuyoshi YOKOKOHJI |

| Associate Professor | Yuichi TAZAKI |

| Assistant Professor | Hikaru NAGANO |

Keywords:

Robotic Hand, Teleoperation System, Haptic Device, Hydraulic Robot, Biomechanics of Human Hand, Walking Robot, Mobile Robot, Environment Recognition, Map Generation, Model Predictive Control

Sensing Device Engineering[MA-2]

| Professor | Isaku KANNO |

| Associate Professor | Hirotaka HIDA |

| Research Associate | Sanghyo KWEON |

Keywords:

Thin film, Sensor, Actuator, Piezoelectric device, micro-TAS, Plant in a chip, Energy harvesting, Thin-film battery, micro-robot, Acoustic device, Piezoelectric thin film, Ferroelectric thin film, Photocatalyst thin film

Advanced Manufacturing Systems[MA-3]

| Professor | Keiichi SHIRASE |

| Associate Professor | Ryuta SATO |

| Assistant Professor | Isamu NISHIDA |

| Research Associate | Kazuki KANEKO |

Keywords:

High speed and high precision machining, End-milling operation, Die and mold, Dental prosthetics, Autonomous and intelligent machine tool, Multi-axis and multi-tasking machine tool, On machine measurement, CAD/CAM, Modal analysis, Mathematical model, Simulation, Motion control, Positioning, Linear motor, Ball screw, Power consumption, Process planning

| Technical Staff | Raita KATAYAMA |

Division of Innovative Materials and Nano Engineering

Nano Electro Mechanical Systems[MI-1]

| Professor | Yoshitada ISONO |

| Associate Professor | Koji SUGANO |

| Assistant Professor | Akio UESUGI |

Keywords:

MEMS/NEMS (Micro/nanomachine), Microsensor, Microactuator, Experimental nanomechanics, Semiconductive nanowire, Multiphysics, Energy harvesting, Micro physical measurement, Surface plasmon, Bio/chemical sensor, Microfluidic device

Materials Design and Fabrication Engineering[MI-2]

| Professor | Toshiji MUKAI |

| Associate Professor | Naoko IKEO |

Keywords:

Macro-and Micro-structure design, Microstructure modification, Strengthening mechanism, Lightweight structural materials, Metallic biomaterials, Bio-degradable materials, Implant device

| Technical Staff | Tatsuya NAKATSUJI |

Cooperative Divisions

Intelligent Production Systems

| Visiting Professors | Hiroshi NARAZAKI |

| Yoshiharu NISHIDA |

Keywords:

Process Control, Iron and Steel Making Process, information systems, Production Systems, Intelligent Control, Optimization, Adaptive Systems, Knowledge-based Systems, Self-organization, Artificial Neural Network Model, Complex Systems

Adaptive Function Model

| Visiting Professors | Shinichiro INOUE |

| Shigeto MIKI |

Keywords:

Nanophotonic Device, Organic Integrated Optical Circuit, Nano/micro Lithography, Natural Language Processing, Machine Translation, Text Analysis, Speech Processing, Speech Recognition, Speech Synthesis

Wisdom-based Manufacturing

| Visiting Professors | Tetsuya KUBOTA |

| Visiting Associate Professor | Hiroaki KAGAYA |

Keywords:

Digital manufacturing, Factory simulation, Facility layout plan, Robot mechanism design, Robot mechanism control, Service robot utilization

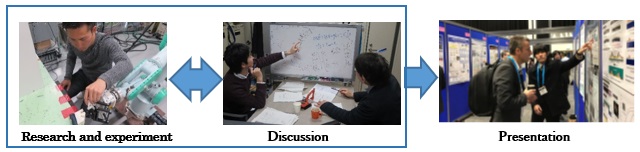

Education

The goal of education in the Department of Mechanical Engineering is to train students to become engineers or researchers who possess originality, application skills, and flexibility based on a solid foundation of experience-backed basic knowledge. For this purpose, the undergraduate course curriculum incorporates not only lectures on specialized basic subjects and specialized subjects but also extensive practical training, experiments, and exercises that effectively supplement the lectures.

All graduate students in the master’s program will be members of one of the laboratories in the department, and will conduct their own research in a specific research field. We cultivate the advanced research capabilities of the students through the conduction of actual cutting edge research, where the faculty and students face off against the unknown issues together, questioning and discussing issues and ideas on an equal footing.

- Mechanical drawing

- Factory training

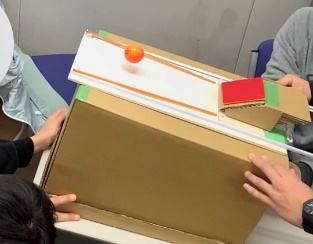

- Creative machine design projects 1

- Creative machine design projects 2

Research Topics

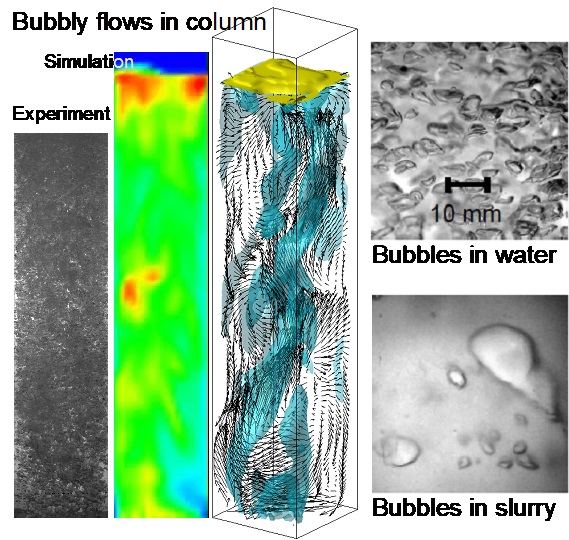

Bubbly flow in bubble column

(Multiphase Fluid Dynamics Lab./Div. of Heat Transfer and Fluid Engineering)

Bubble column reactors, in which complex bubbly flows are formed, have been widely used in various practical systems. Experiments and numerical simulations have been carried out in this lab to understand the complex flow structure in detail. Effects of fine particles, which drastically change the bubble size distribution in slurry bubble columns, are also being investigated.

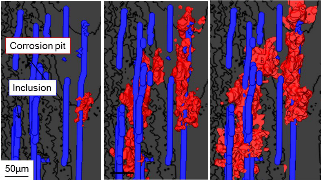

Observing fatigue crack initiation process by ultra-bright X-ray

(Structural Safety Evaluation Lab./Div. of Material Physics and Mechanics)

The figure shows an example of CT imaging showing corrosion fatigue crack initiation process in high-strength aluminum alloy. This image was obtained by ultra-bright synchrotron radiation X-ray, and clearly shows that corrosion pit (indicated by red) is formed around inclusion (blue), and grew along it beneath the surface.

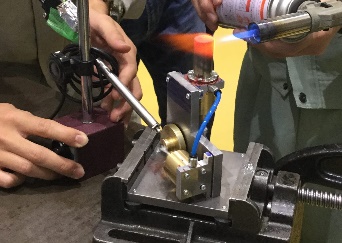

Machining parts with complex shapes with high accuracy

(Advanced Manufacturing Systems Lab./Div. of System Design)

Machine tool technologies including mechanical components, motion control technologies and advanced industrial software technologies play key roles in the industries. Advanced manufacturing systems laboratory developed the high-speed and high-precision machining technology for jet engine parts based on the modeling and control technologies for multi-axis controlled machining centers.

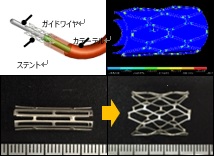

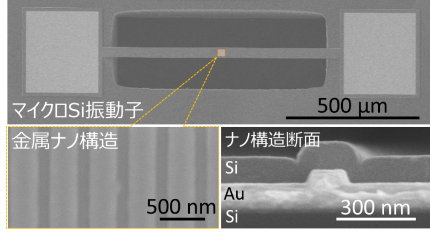

Realizing nano-scale sensors

(Nano Electro Mechanical Systems Lab./ Div. of Innovative Materials and Nano Engineering)

This division promotes advanced researches on optical sensors used for high-capacity information communication and analysis of biomolecules such as a detection of single molecule DNA, which integrate metal nanostructures on micromechanical structures. Nano and microscale manufacturing technologies can realize advanced functional sensors.

Messages of International Students

Nor Elora

【Undergraduate student from Malaysia (April 2014-March 2018)】

Kobe University is where my dream was fulfilled. To be able to study here in Kobe University has been the greatest experience in my life.

Now, I am an undergraduate student in my fourth year. I can say studying here has been a humbling journey. The teachers here are not only rich in knowledge but also kind, helpful, and down to earth. The community here is very friendly and caring too. Kobe University also offers tip top facilities where you can enjoy studying here with a peace of mind.

Here in Kobe University, I was able to meet a lot of people and experience cultural exchange.

When I graduate from this university, I will be returning back to Malaysia with a great opportunity of applying this invaluable experience and knowledge that I gained from here.

(This message was given in 2018.)

Toojin Kim

【Alumna from Korea】

It has been a great experience for me to study at Kobe University. During my undergraduate, I met some incredible professors, tutors and friends and they helped me a lot to expand my experience. Also, the programs in mechanical engineering are well designed for students to experience in various field, so it was possible to find my specific research interests. In addition, I was influenced by the beautiful landscape of the city of Kobe. Mt. Rokko and seaview of the Kobe are in itself fascinating. It is the most wonderful thing to be able to study in such a beautiful city.